|

|

|

|

|

We have a comprehensive ability of development and upgrade on hardware and software, We have reached the following improvements, and will provide upgrade services for customers.

|

|

|

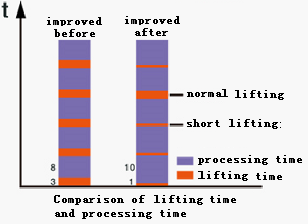

1.PULSING TOOL LIFTING

Up parameter, short tool lift, controlled by ten digits.

1) Compared to the same previous params of tool lifting, a 15% processing time is increased, and a 30% speed is improved when processing the bone positon.

2) More continuous discharging

3) The smaller DN parameter can be used under special circumstance, the processing efficiency is not affectted.

|

|

|

|

|

|

2.LOW CURRENT PROCESSING, MORE STABLE Servo algorithm is improved, and the processing efficiency of the range of 0.5A ~ 3A is improved by 10%.

3.FINE PROCESSING SPEED

The fine processing speed of C825 and C810 is improved by 20%。

4.CUSTOM SERVO VOLTAGE

The original set of stalls is from 0 to 9. In order to solve the software problem that the servo stall gap is too big, the actual servo voltage which can be setted by customers is from 11 to 200.

|

|

|

Test Cases

|

|

The test resluts have the following performance improvements which are very stable.

|